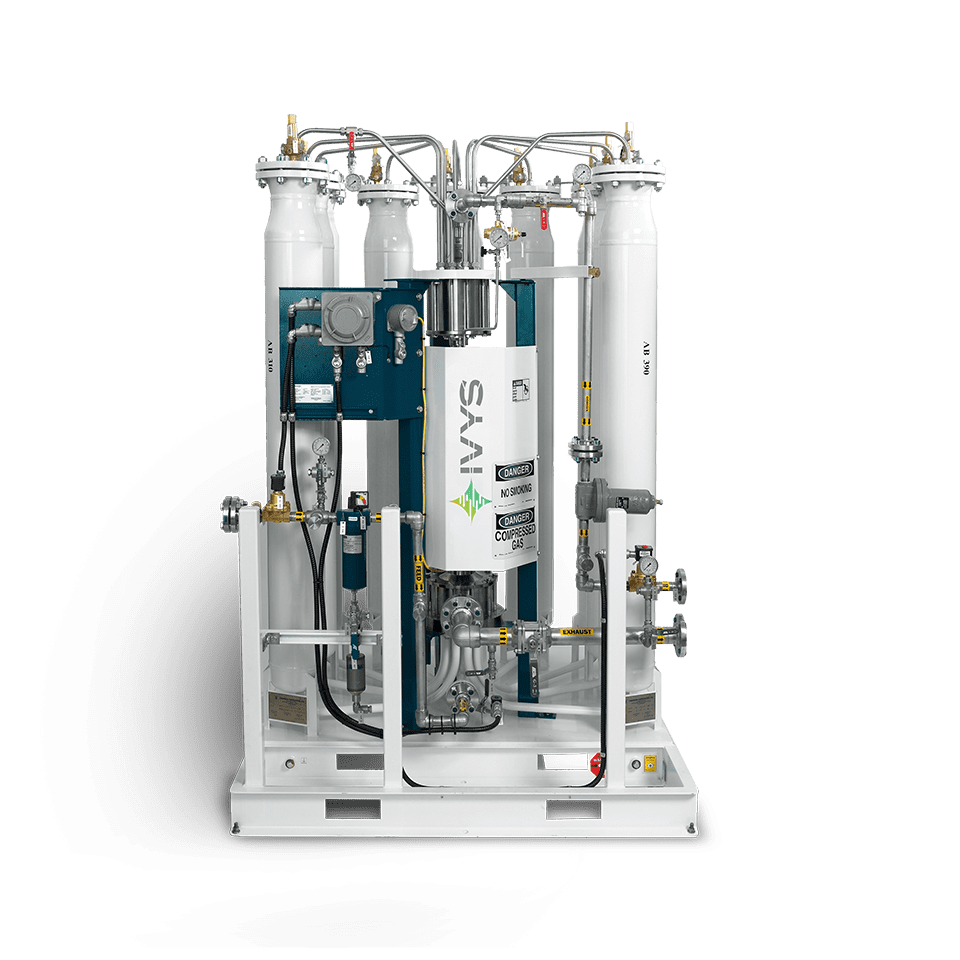

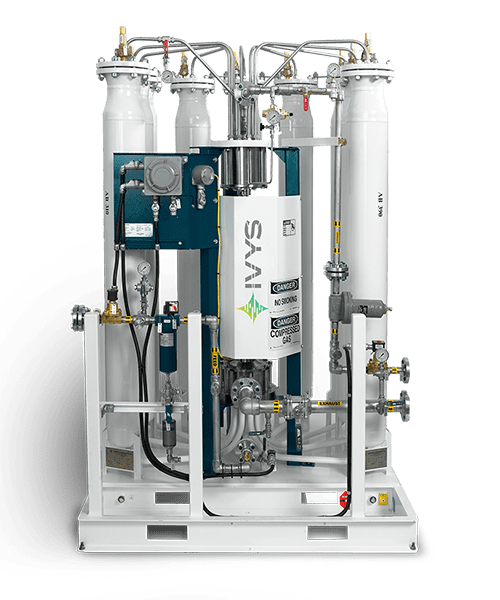

PSA

Specialized gases

Conditioning

Helium Purification

Helium, a scarce, non-renewable gas, is used in the production of fiber optic equipment and semiconductors. Other industrial uses of helium include optoelectronics, laser welding, cold gas spraying, chemical processing and leak detection. Rising demand and declining reserves of helium have led to dramatic increases in the price of helium, intensifying the market for helium recovery systems.